Introduction of SCADA Training:

SCADA Training at IdesTrainings- The SCADA is the process of getting the real time data from different locations, and the information is gathered by the SCADA system and then they analyze it, control it and analyze the processes. This is the combination of the data acquisition and the telemetry. This collects the information from the different processes, like information about the temperature; it carries about the necessity and required information. IdesTrainings offers best SCADA Training by high professionals with real time examples.

The supervisory control and data acquisition is mainly used for organizations to check all the data that is useful for future purposes. It controls and maintains all the information. IdesTrainings also provide both SCADA Online Training and SCADA Corporate Training courses. For more details about PLC SCADA Online Training contact our help desk.

SCADA Online training Outline details:

- Mode of Training: SCADA Online training/ SCADA corporate training/Devops Virtual Web training.

- Duration Of Program: Can be optimized as per required(30 Hours).

- Materials: Yes, we are providing materials for best SCADA online training.

- Course Fee: please register in our website, so that one of our agents will assist you.

- Trainer Experience: 10+ years.

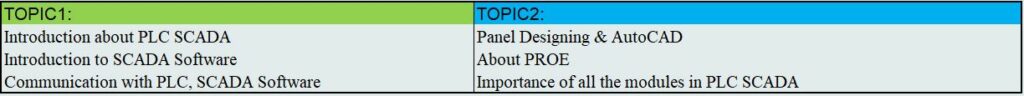

PLC SCADA ONLINE TRAINING COURSE CONTENT

Overview of SCADA Training:

The SCADA Training- SCADA stands for Supervisory Control and Data Acquisition provides you the concepts, fundamentals involved in SCADA. Let us discuss all those concepts during the PLC SCADA Online Training by well experienced Trainers.

Concept of the Control operations in SCADA Training:

- To perform the supervisory operations there are some key attributes of the SCADA system. For example, taking the general model of the SCADA system, there are few levels that are level A, level B, level C, level D and level E.

- This is the example of the functionality of the manufacturing system, each level follows different operations like level A, that device will control or find out the temperatures and the final control elements.

- Then the level B will contain the industrialized input modules and the output modules, and their processors.

- The level C will supervise the computers and then it collates the information and then provides the operator control views.

- Then the level D will control the production level which is related to the monitoring the production and targets. And the last one, level E is the production schedule level.

Learn concept of SCADA components in PLC Scada Online Training:

- The foundation of the SCADA system, assembling data on top of the procedure and transferring organizing information to the field associated devices.

- By increasing the integrity of the system the multiple servers will often be configured in a dual-redundantor hot-standby formation as long as constant control and examine in the event of a server malfunction or go down.

- The single PC SCADA systems may collect supervisory computer, in which controls the HMI is an element of this computer. In SCADA systems, the master location may consist of more than a few HMIs hosted on consumer computers, an assortment of servers for data in advance, separated software submission, and failure revival positions.

- It refers on the technique to the computer and software responsible for exchange a few words with the field association organizer, which be RTUs in addition to PLCs, and comprise the RTU software running on operative workstations.

- Human Machine Interface we call it as HMI in Short it’s a software facilitates interaction with field devices it processes and sends it to a human operator where they can monitor or control the system. The supervisory system gathers the data and sends commands or operations like Pumps valves and motors etc., SCADA Software is the ability to log data for historical purposes.

- This means the plans had to maintain personnel on site during production in order to control the processes as manufacturing grew and sites became more remote in nature relays and timers were used to assist in the supervision and control of processes with these devices employed, fewer plants personal were required to be on site in order to oversee and control operations.

Utilities of SCADA:

Automated that is used in industries such as energy oil and gas water the system has centralized system that monitors and controls entire sites ranging from an industrial plant to complex of plants across the country a complex of plants across the country SCADA system works by with signals that communicate via channels to provide the user with remote controls of any equipment.

- Controlling industrial plants via processors become a reality in the 1950s gas and oil, utilities and manufacturing where major users working these new technologies and Finally the communication infrastructure delivers connectivity to the supervisory system.

- Then to the RT and PLCs for users to command the communication infrastructure to relay data from remote are to use RT and PLCs which runs along electric grids water supplies and pipelines communication is absolute most essential link for a SCADA operate properly system manages communications from HMI. Supervisory System Controls after telemetry came on the scene to offer even more remote capabilities.

Fundamentally another decade later the term SCADA was used to describe systems with PLCs and microprocessors that are being used for the monitoring and control of automated processes on an even greater scale than ever before SCADA systems are crucial for industrial organizations, back then was anything but practical they maintain efficiency process.

Industrial operations of SCADA can be learned during SCADA Training:

- In this operation there are few system field devices that are installed in the system. They are involved in the various processes, like monitoring the processes and then send other operations, like there is the protection relay that is used for protecting of the power.

- The PLC and the RTU these control the control power logics, these are the operations that control the IT or these will integrate all the systems in the organization, mostly they are used in the large organizations.

- The SCADA system is the thing that will permit you to do what you require for the association, but not with essentials stands for supervisory control and data acquisition (SCADA) system.

- It is a system that is used for controlling, monitoring and analyzing in the manufacturing process, These systems are used in all the organizations in order to control that system so that a means which is a software that is used to control hardware and which might be anything like PLC tri series in which is also with wiring the data from Ms devices.

- So it is controlling and requirement is no one like area network control systems what is personal resources that need to work together and gas pipeline water distribution system scanner system out of Limited systems developed the space programs at that time everything you did not know and with the development of microprocessors and integrated circuits microprocessor based geometry systems development information.

Concept of abilities and facilities with SCADA in SCADA Online Course:

- SCADA Process in the world which means it is software which is used to control hardware which could be anything like PLC, drives, servers and which is also acquiring the data from these devices so it is controlling and acquiring. We are best in providing SCADA Training by real time experts from India at flexible timings.

- In this world wide area network control systems control that need to work together like oil and gas pipeline, water allotment system of address system zest money revolution the over much greater distances history of SCADA system out of with geometry systems developed for the space programmers at that time everything will not be no and women development.

- All the information and at the same time telemetry was being used supervisory control and data acquisition and the water inside office.

- The SCADA Training which is the supervisory control and data acquisition, which gives the insight, look for the operators and the stake holders that what is happening exactly in the organization.

- The integral things scan the data from your facilities and then display it inside the advanced visual and monitoring system. This data gives you the critical information and gives ability to run your facilities more safely and reliably.

- The adjustments are done based on the customers, procurement requirements; we use the better software to provide the better facilities, which includes the data services like designing program, testing, etc.

- With this SCADA the facilities can get more advanced and operates your facilities more efficiently.

Fundamentals of SCADA in SCADA Training:

In SCADA Training, there are different network topologies, in theses we have the SCADA, the SCADA actually is the thing which connects to the one system to another system, and like this might be some kind of the security system. This can control the systems which are inter-related. For example there are two systems then, the first system can be controlled by the second one and the second system can be controlled by the first system.

Development by PRO E in PLC SCADA Training:

- The PRO E software offered because it is an important and scalable designing platform. Which is extensively used software along with the Mechanical & Automobile engineers for designing whole 3D models of the manufactured goods.

- The information by means of the obtainable collection of tools allows the client to manufacture for collaborative development. PROE is the CAD/CAM software, which is developed by PTC, Parametric expertise business which be a complete set of conception design, 2D, 3D, simulation & analysis business software, and this is a Future based parametric software which is Bi-directional, associate and interactive one.

- PROE is one of the important software used in many purposes.

Capabilities of CREO can be explained during SCADA Online Training:

- In Scada Training- The CREO is a packed through the number of latest improvement and abilities towards to assist your proposition and about the products of the future. Creo Parametric is the new user interface.

- This CREO permits you in the way to access the instructions without difficulty. This can permit you to work through your model, describe the geometry you desire to perform and streamline the design process for you. Idestrainings is best in providing SCADA Training with live projects by experts.

- In Creo, the constraints which will be used in Creo are given explanation. Constraints are extremely essential in draft. Through the sketch, you might be aware of signs like H, V, T and R. Which are known as constraints signs. Whereas H is the horizontal, V means for vertical and T stands for tangent constraint here the similar manner R stands for like radius constraints.

Learn the Concepts in Ansys in PLC SCADA Online Course:

- ANSYS: It is and the set of elements software in addition to this means assist to manufacturing repeat the reply of physical element or system to dissimilar type loading.

- ANSYS Tools will be particularly helpful in resolving some kind of problems in these kind of fields mechanical, fluid, thermal, electrical and in addition to magnetic problems. Ansys will be helpful for the generation of the 3d form products, for the engineering it will be practical.

Learn the importance of CATIA during SCADA Course:

- CATIA is generally used all through the engineering business; particularly in the mechanical sector. Since it is accommodating and which is headed to draw the plan of the merchants.

- Here firstly CATIA known as CATI, which is named as Conception Assisted tri-dimensionally interactive (CATIA).

- Further the AUTO CAD is very much required for drawing the plan prior to learn the CATIA. The CAD Software is too desired to be meant for this CATI.

- CATIA contended here in the market with Siemens NX, pro/engineers and many other things like solid works and solid edge. This is written in C++ language.

- Catia Training will be helpful to learn SCADA Training. We also provide you the best Catia Training by Professionals having years of experience.

There are many Trainings that are related to SCADA Training. Automation Training, Allen Bradley PLC Training, Siemens PLC Training, Hmi Scada etc., the basic concepts of these courses can be explained during the SCADA Training.

Conclusion of SCADA Training:

Register for SCADA Training at IdesTrainings with practical examples by our team experts. We also provide you the SCADA Training materials during the regular sessions of Training. All the advanced techniques in PLC SCADA are explained with practical examples. We provide this course with reasonable price.

To know the basic concepts and advanced modules of SCADA, join PLC SCADA Online Training, we also provide you the SCADA Training demo video by our team experts.